Safety costs vs. recall risks

Safety costs vs. recall risks

"Manufacturers should take preventive measures to minimise risk of recalls. However, having a corrective action plan during a recall is equally important."

Kapil Bansal

Global Head of Consumer Products and Retail, TÜV SÜD

Wednesday, September 6, 2017

When Samsung faced product recalls last year for its Galaxy Note 7, the company estimated that the case would cost it over US$5 billion. But the South Korean giant is not alone. Plenty more product recalls have been issued since – with a variety of manufacturers this year asking customers to return items from children’s toys and car seats to washing machines and frozen pizzas.

For manufacturers, managing product recall risk can be a major headache. Rigorous testing and quality control allows manufacturers to drastically reduce the risk of recall. But the cost of this testing needs to be weighed against product cost. As high prices can be off-putting for customers, manufacturers are often wary about spending more on testing.

That said, in the modern, connected world, news of product recalls spreads like wildfire across the Internet, amplified by the advent of social media. This often causes substantial and lasting damage to a company’s reputation. Mounting e-waste-related environmental concerns also come into play. Modern customers value sustainability, and the idea of landfills piling up with faulty electronics and the like has become very disconcerting.

But what do companies and consumers really need to know about the risks of product recall? And how can we as a society go about minimising them?

Manufacturers will be pleased to learn that there is plenty of research out there to help provide key insights into the increasingly important topic of product recall.

One example is the Grocery Manufacturers Association’s white paper, Capturing Recall Costs. The paper found that “over 81 percent of survey respondents describe the financial consequences of a recall as either ‘significant’ or ‘catastrophic.’” The top four business impacts include: business interruption or lost profits, recall execution costs, liability risk and reputation damage, or loss of brand equity. About 77 percent of respondents estimated the financial impact to be up to US$30 million, with the remaining 23 percent reporting even higher costs.

Worryingly, the paper also predicts that recalls are becoming more common, and look set to increase in both frequency and severity. An increasingly complex product supply chain means that recall from a single supplier can have a much wider ripple effect for its downstream manufacturers and customers. With improved product traceability, it locates the origin of product non-compliance more easily as well.

Regulatory authorities are also stepping up their efforts. The European Commission works with national authorities in the EU to remove dangerous products in stores, through a Rapid Alert System. The latest report highlights the Commission’s cooperation with e-commerce sites such as Amazon, Ebay and Alibaba to more proactively tackle the issue of non-compliant products.

Nielsen last year also reported that brand equity can take a lasting hit in the event of a product recall, stating: “Recalls can seriously affect consumer sentiment and damage a company’s reputation and the brands in its portfolio.”

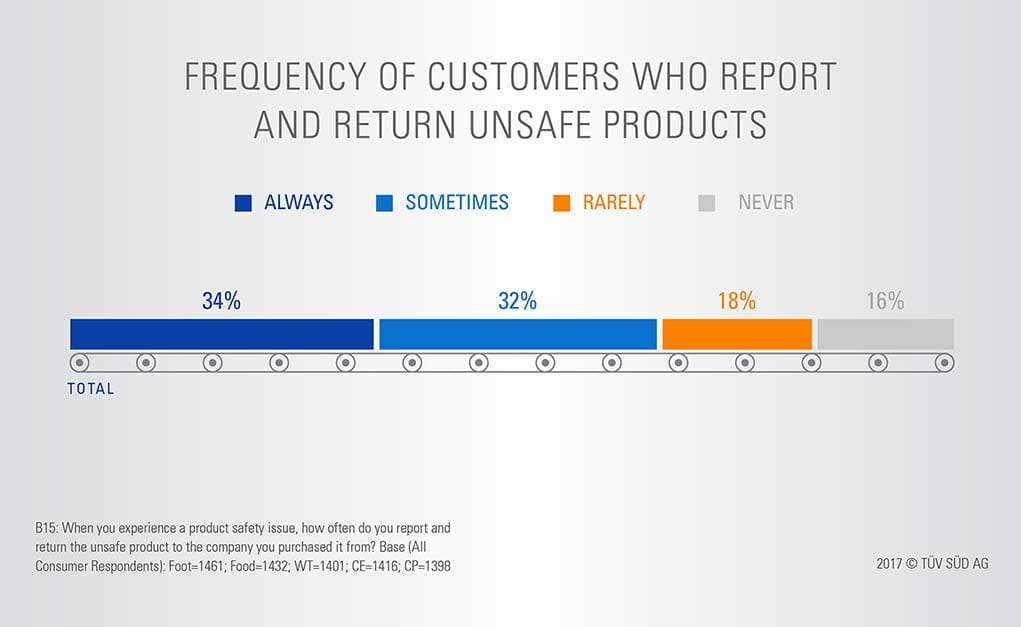

TÜV SÜD’s 2017 Safety Gauge report has discovered that most businesses feel they are doing enough to provide safe products. The report also found that some 34 percent of companies have had to issue product safety recalls in the past five years. On average, 66 percent of consumers said they “always” or “sometimes” return products they believe to be unsafe.

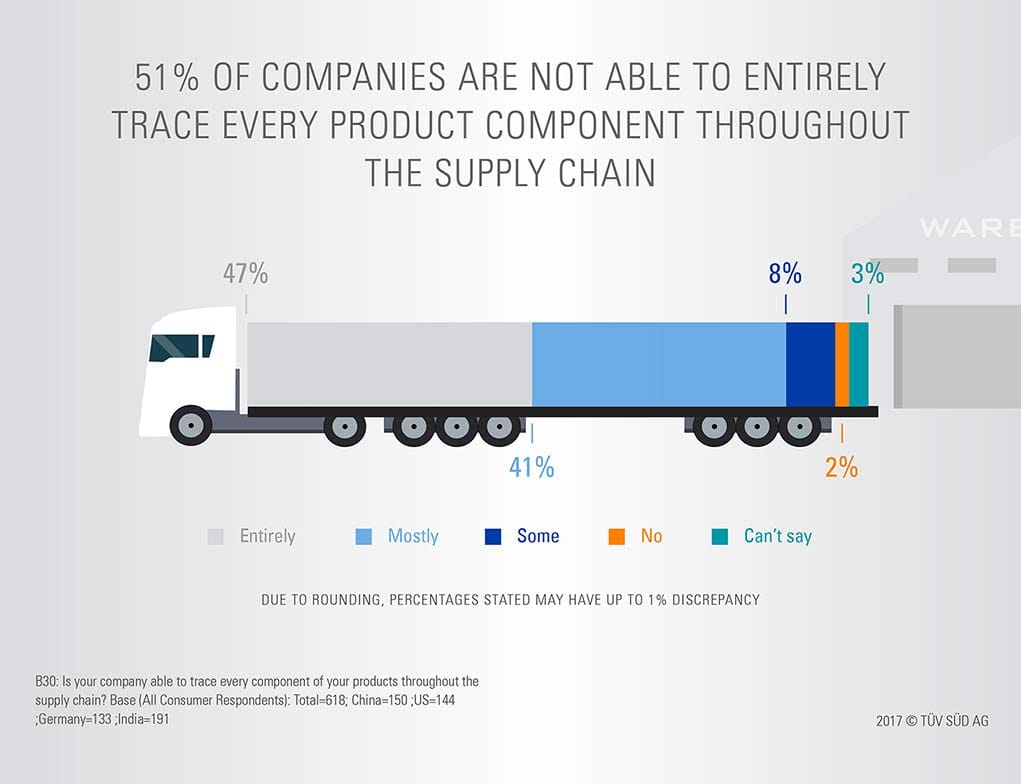

Among the businesses interviewed for this report, more than 50 percent were unable to trace every component of their products throughout the supply chain.

Kapil Bansal, TÜV SÜD’s Global Head of Consumer Products and Retail, believes that the recent spike in product recall has two root causes. “In the United States, recent changes in regulations have increased the severity of penalties and also created a reporting database for customers,” Bansal said. “The other factor is social media, where information about products – both correct and incorrect – can spread at a mind-boggling pace.”

But there is also reason for cheer. The good news for both the business community and consumers is that the cost of safety is coming down. TÜV SÜD’s Safety Gauge research asked business decision makers to indicate the mean increase in production costs needed in order to achieve the best product safety standard. Results show that this cost increase has fallen since 2012. On top of this, 84 percent of consumers have expressed a willingness to pay a premium for safer products. This means that increased spending on product safety could in fact be lower than the business costs of a potential product recall. Increased product safety with a neutral impact on company profits, it seems, is a distinct possibility in many cases.

Ben DeVito, TÜV SÜD’s Global Sales and Technical Director, says that companies can adopt practices that help them reduce recall risks. He notes, “Some good measures include making sure you really know your product category – venturing out into the unknown is usually a bad idea. It is also worth getting to grips with regulations pertaining to your product. Make sure you test and file documents in accordance with locally applicable regulations.”

“If you supplement this with a risk-based approach to testing and management, as well as adequate supply chain training, you’ll find yourself on the right track,” says DeVito.

Bansal concurs. “An understanding of regulations that apply in the regions you are operating in is imperative,” he says. “It is not enough for companies to simply consider product safety. They also need to know exactly what steps to take – and who they have to report to – should an issue occur.”

This evidence seems to suggest that companies must now become increasingly aware of the risks of recall – and look for proactive ways to prevent, rather than cure, safety issues.

Although some big companies feel they may be able to absorb the cost of a recall, the evidence shows that recalls are exceptionally costly, financially and non-financially; time-consuming and environmentally unsound. They have become less desirable than ever as the world edges towards a more sustainable future.

Customers are now voting with their wallets. They want well-tested, sustainability-guaranteed products that will not be recalled. They want items that last longer and provide an exceptional user experience. And they are even prepared to spend more to get them.

The jury has ruled on the product recall risk issue. If a company’s biggest priority is its customers’ safety, it will also ensure that their business goals are achieved, and everyone wins – from end-users to manufacturers.

Find out more about our Consumer Products & Retail services.

Explore growing product safety issues

Learn more

Connect with the latest business practices and consumer insights

Learn more

Sélectionnez votre emplacement

Global

Americas

Asia

Europe

Middle East and Africa